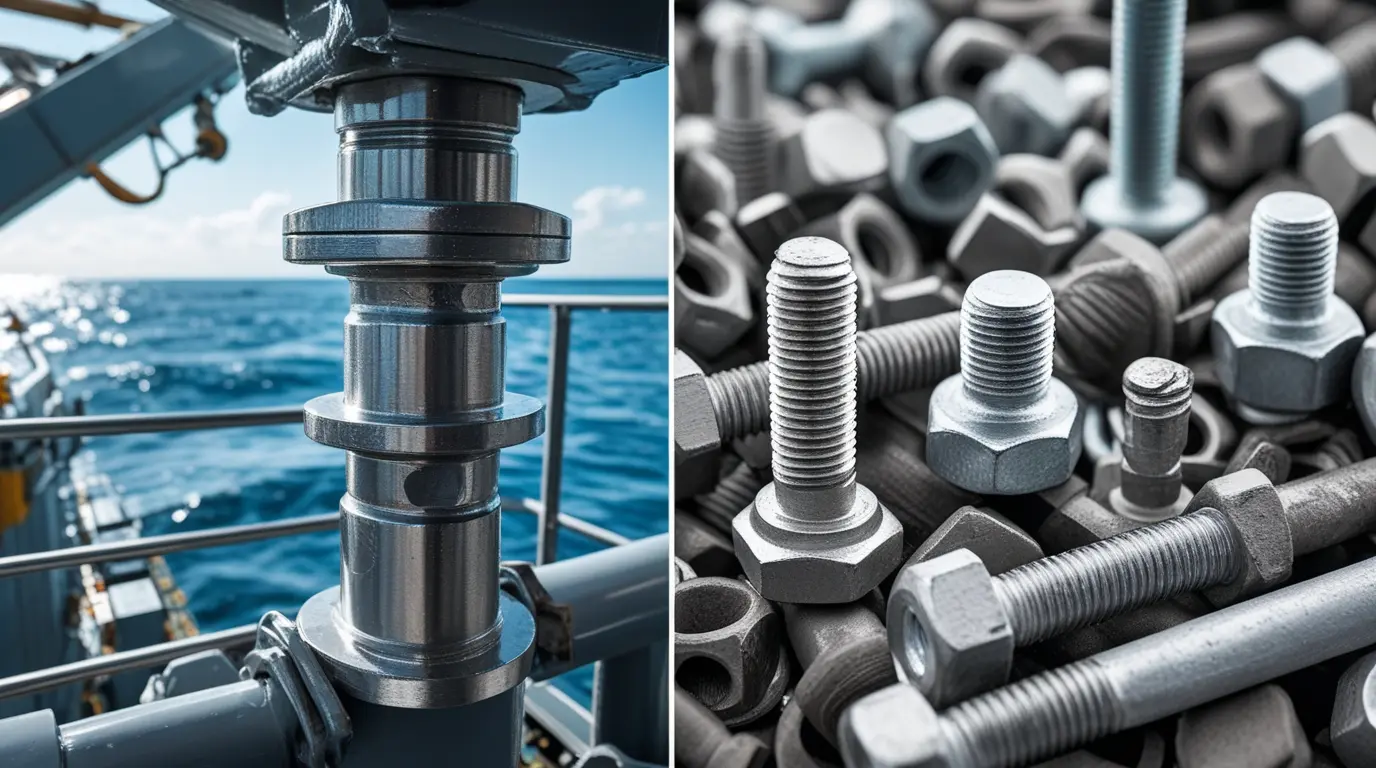

Stainless Steel 316 vs. Galvanized Nuts and Bolts: Key Differences and Use Cases in Construction

When it comes to fasteners, not all nuts and bolts are created equal. Choosing the right material is essential for ensuring strength, safety, and durability in any project — whether it’s for industrial construction, plumbing, or mechanical applications. Two of the most common materials used are stainless steel 316 and galvanized steel. While both have corrosion-resistant properties, they perform differently under various conditions.

What is Stainless Steel 316?

Stainless steel 316 is an alloy that contains molybdenum, giving it superior resistance to corrosion, especially against chlorides and marine environments. It is one of the highest grades of stainless steel used for nuts, bolts, and fittings.

Key Features:

- Excellent resistance to pitting and crevice corrosion.

- High tensile strength.

- Long lifespan with minimal maintenance.

- Aesthetically appealing with a polished finish.

Typical Applications:

- Marine environments (shipbuilding, docks, offshore platforms).

- Chemical plants and pharmaceutical facilities.

- Food and beverage processing (due to its hygienic properties).

- Outdoor structures exposed to saltwater or harsh weather.

What is Galvanized Steel?

Galvanized steel bolts are typically made from carbon steel coated with a layer of zinc through the galvanization process. This zinc coating protects the underlying metal from rust and corrosion, though not as effectively as stainless steel 316.

Key Features:

- Cost-effective compared to stainless steel.

- Adequate corrosion protection in mild environments.

- Good mechanical strength.

- Readily available in the market.

Typical Applications:

- Construction and structural projects.

- General plumbing and piping support systems.

- Agricultural and outdoor equipment.

- Applications where cost is a primary concern.

Key Differences Between Stainless Steel 316 and Galvanized Steel

| Feature | Stainless Steel 316 | Galvanized Steel |

| Corrosion Resistance | Excellent (especially in saltwater & chemical exposure) | Moderate (suitable for mild outdoor conditions) |

| Strength | High tensile strength, durable over time | Strong, but zinc coating may wear off |

| Maintenance | Low — resistant to rust & stains | Requires periodic inspection for rust/corrosion |

| Appearance | Smooth, polished, modern finish | Matte, grayish appearance |

| Cost | Higher upfront cost | More budget-friendly |

Which Should You Choose?

The choice between stainless steel 316 and galvanized steel depends on your project’s environment and long-term requirements:

- Choose Stainless Steel 316 if you are working in highly corrosive environments, such as near the sea, in chemical industries, or where hygiene is critical.

- Choose Galvanized Steel if your project is cost-sensitive, indoors, or in mild outdoor environments where extreme corrosion is not a concern.

Final Thoughts

Both stainless steel 316 and galvanized nuts and bolts play an important role in construction, mechanical, and plumbing industries. At RZ Oman, we source and supply a wide range of high-quality fasteners, ensuring that our clients get the right material for their specific applications.

When in doubt, consult with a materials expert to evaluate the conditions of your project and make the best long-term investment in safety and durability.